WHAT IS THE BEST DRONE FRAME?

If you are a racing drone enthusiast, you will know how important it is to get the perfect drone frame. So, the question now is: how can we make the best drone frame and what would we say are the characteristics of the perfect drone frame? This article will answer these questions for you.

To make the perfect drone frames, you must take the following into consideration.

1. The structural design of the frame must be reasonable.

Most of the parts of the drone are easily replaced. This is because these parts are found in the drone kit, except for the carbon fiber parts. You need to consider the ease of installing and replacing damaged accessories.

You should also consider the location of the battery; the site of the fixed battery should be at the center of gravity. Secondly, the frame of the drone must provide protection for the camera. If the drone will be used by a photography enthusiast, the camera should be rotatable. So, the space and height of standoff need to be considered.

2. The choice of materials

It is common knowledge that carbon fiber is the prime material of choice for the FPV/UAV drone frame. The T300 material is the most widely used material in carbon fiber because it is relatively inexpensive. However, if you choose the T700 carbon fiber as the main material for all the parts of the drone such as the arms, the main plate and the bottom plate, the cost will be higher. It is obvious, however, that that the T700 is stronger than the T300. We have compared the data for the T700 and the T300 and the reason as to why it is a better option is found in the PDF. The T700 carbon fiber provided by Jinjiuyi is used to cut the drone frames. Before, the arms and frames were easily delaminated and softened. However, the carbon fiber provided by Jinjiuyi these days are no longer delaminated, thus, they are now harder and more durable.

3. The drone frame styles

There are frames for tricopters, quadcopters, hexacopters and octocopters. Each of these different frames have different applications. Few people find use for the tricopter, however. Generally, racing drones or freestyle drones are mostly 4-axis quadcopters. The hexacopters are mostly used for photography or as agriculture drones. The octocopters are mostly long-distance flying drones. They find use as agriculture drones, police or army drones, etc.

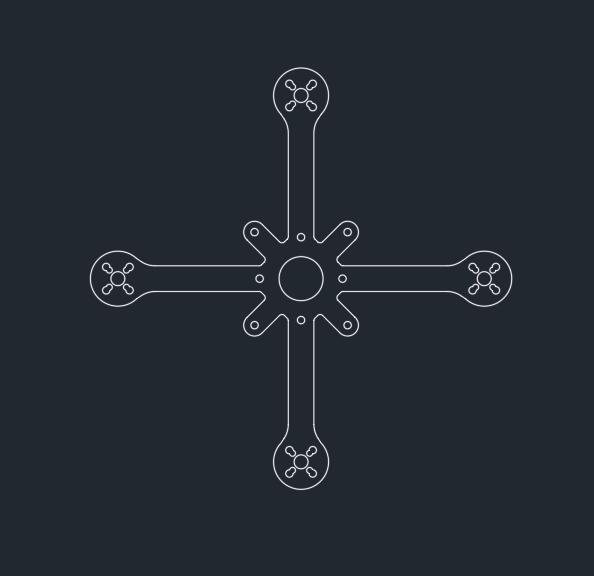

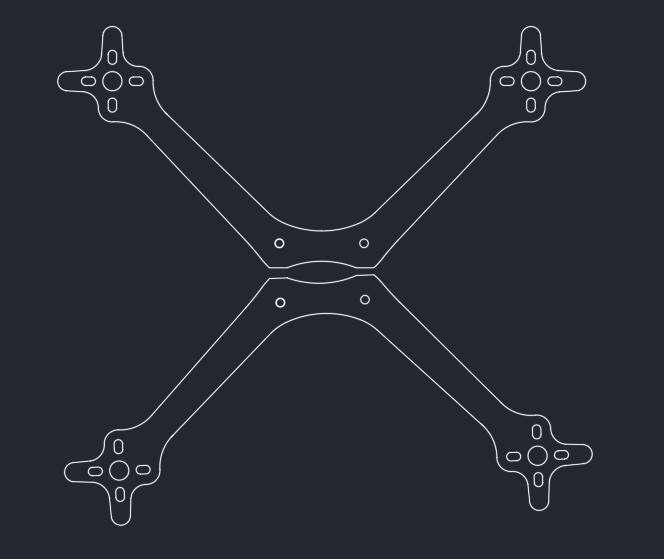

Is the quadcopter unibody x-frame or separate frame?

The major advantages of the unibody frame are its high stability and easy assembly. Its major advantage is the quantity of material wasted while cutting the carbon fiber plate. Also, one carbon plate can only layout a few frames and if a single arm is damaged, it implies replacing the whole frame. This is very expensive.

The separate frame designs are usually favored over the unibody frame because it is relatively inexpensive and easier to repair. Split arm designs are usually less expensive than unibody frames because a lesser quantity of carbon fibers plates is wasted when constructing them. The fact that they are replaceable also makes them lighter because you can design the arms to be narrower if you want. Also, if an arm is broken, replacing them is easier, quicker and at a lower cost.

4. Choosing the right size

The sizes of the frames for different applications:

Frame size | Prop size | Application |

280mm+ | 7 inches | Long range/freestyle/racing |

250mm | 6 inches | Long range/freestyle/racing |

210mm | 5 inches | Freestyle/racing |

180mm | 4 inches | Freestyle/racing |

150mm | 3 inches | Freestyle/racing |

112mm | 2 inches | Freestyle/racing |

100mm- | Whoops | Indoor/limited outdoor |

According to our company’s data, we cut all sizes of drone frames, including large size drone frames. But most of our customers require custom cut quadcopter frames. This feature is used in both freestyles and racing drones, because it is the best compromise between strength, weight and responsiveness.

In addition, some countries have adopted restrictions on drones, stipulating a size smaller than the government-specified size. These restrictions are usually made to prevent them interfering with aviation aircraft while flying outdoors.

5. Carbon fiber thickness

It is obvious that the thicker the carbon fiber, the heavier the drone frames. So, the question is: where should you put the thick carbon?

The first place is the arm, the arms take most of the hit and are most likely to fall off during the flying or racing. If it is not strong enough, it will break or deform easily. Presently, most customers choose a 5mm carbon fiber to cut the arms. Even companies like AstroX choose a 5.5mm or 6mm carbon fiber in some of their projects.

The second place to consider is the bottom and top plate. These places usually take big impacts and hold the drone kits together as well. They usually designed with 3mm carbon, but you can use 2mm carbon if you want to achieve a lighter weight.

The third place to consider is the bumper. Some frames are designed with bumpers. They are usually done with 2mm thick carbon fiber.

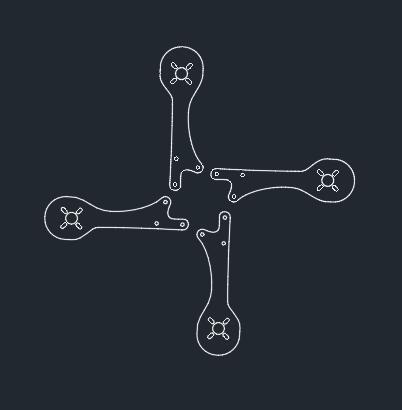

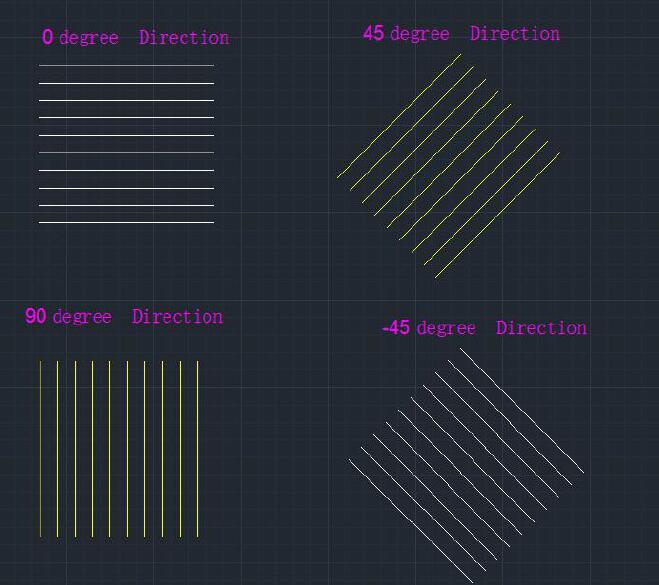

6. The direction of the arm/frame during CNC cutting

This one of the most important factors to be considered besides choosing the materials. The x-frame has the highest cutting strength in the 45-degrees direction, and the split arm has the highest strength in the 90-degree direction. The number of the 45-degree and 90-degree layout on the same carbon plate is different. This is why the 45-degree cutting direction is more expensive than the 90-degree direction.

7. The surface treatment of the frames

Some of our customers choose the chamfering and painting/coating process. This because carbon fibers usually have sharp edges after they have been cut.

The edges are chamfered so the sharp edges do not cut your arms while assembling or flying the drone. It also gives a more beautiful look and a higher-quality feeling after it has been chamfered and painted. These are the services we provide at Jinjiuyi.

8. The design of the screw holes

Many designers use a press nut on carbon fiber.

The press nut is snapped into the hole of the carbon fiber with a great external force. There is a design to prevent sliding. Using the press nut makes the fastenings very strong and erases the worry of the components falling apart.

9. Who should cut these frames for you?

It is very important that you choose a very experienced carbon fiber manufacturer. This is what ensures the quality of your frames.

Jinjiuyi has been in the carbon fiber manufacturing industry for a very long time now. We have helped many well-known companies producing the most popular brands to cut their drone frames. In our six years of working in the industry, we have acquired a wealth of invaluable experience in cutting UAV/FPV drone frames.

In a nutshell: choosing Jinjiuyi is your best choice!

Pulished on Jun. 14, 2025

Pulished on Oct. 23, 2023