Carbon fiber tube roll forming:

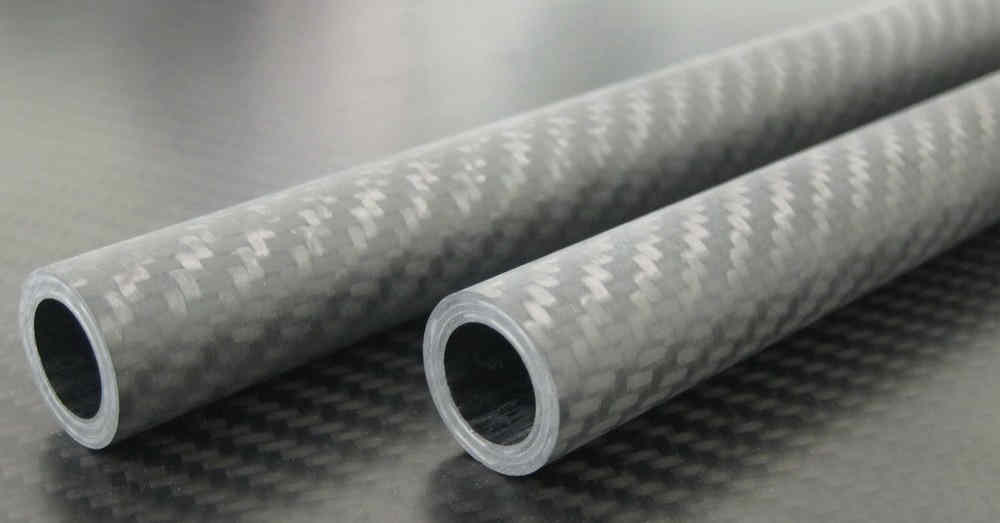

Carbon fiber tube is a typical product in composite materials. It is a common structural component in the aerospace structure. Some large satellite antenna brackets mostly use carbon fiber tubes. They are usually formed by filament winding, pultrusion, roll forming, etc., in which the roll forming process is the most common, this article we will take a look at the carbon fiber tube roll forming.

First, we need to cut the required carbon fiber pre-dip and prepare the inner core mold according to the pipe specifications. A layer of release agent is applied to the surface of the inner core mold, and then the carbon fiber prepreg is uniformly rolled onto the inner core mold by a coiler, and finally a layer of OPP tape is wrapped. The pre-production steps for the carbon fiber tube have been completed. Then, these carbon fiber tubes are sent to the oven, solidified in a high temperature environment, and after waiting for cooling, the OPP tape is torn off, and a carbon fiber tube first embryonic is obtained. It is usually necessary to post-process the carbon fiber tube. The usual method is to spray the paint. Spray the matte or glossy paint according to the requirements, and cut off the uneven parts at both ends, and finally obtain the finished carbon fiber tube.

The most notable feature of carbon fiber composites is their light weight and high strength. The weight reduction effect of carbon fiber is more prominent than that of aluminum alloy, but the strength is better than most metal materials. In order to better play the advantages of carbon fiber for metal materials, a more reasonable design is necessory. Carbon fiber tubes have the following characteristics: high operating temperature, corrosion resistance, and anti-aging, which are favored in many applications.

Shenzhen Jinjiuiyi Electronic Technology Co., Ltd. integrates carbon fiber plate, carbon fiber tube and carbon fiber CNC processing. The company has large-scale hot presses, autoclave, hydroforming table and CNC cutting machine, providing customers with different specifications such as T300 and T700, high quality carbon fiber products and processing services.

Previous:

How to produce carbon fiber tube?

Previous:

How to produce carbon fiber tube?

Pulished on Jun. 14, 2025

Pulished on Oct. 23, 2023